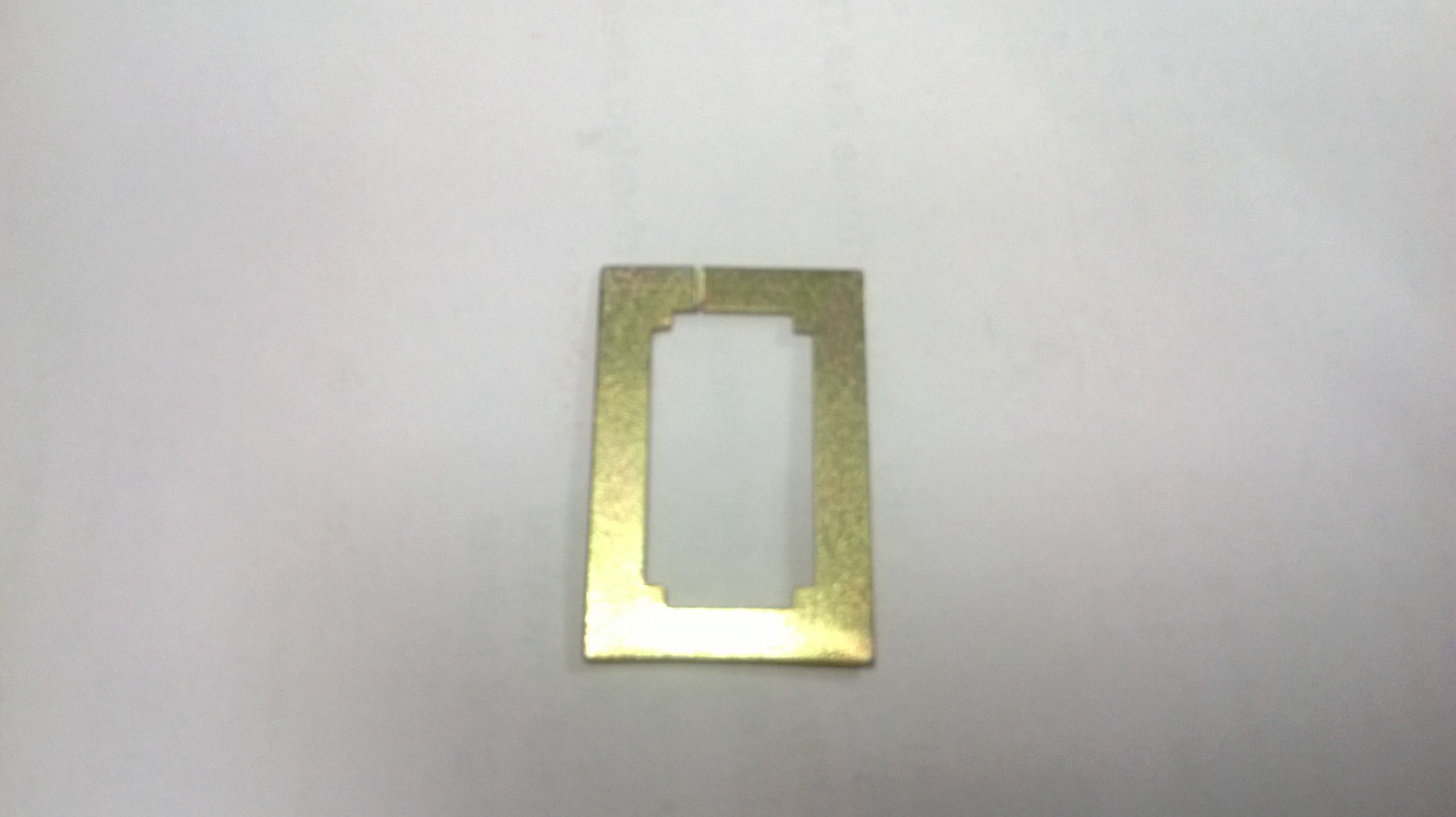

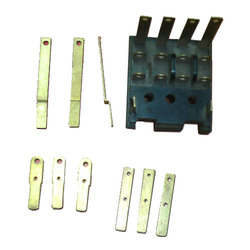

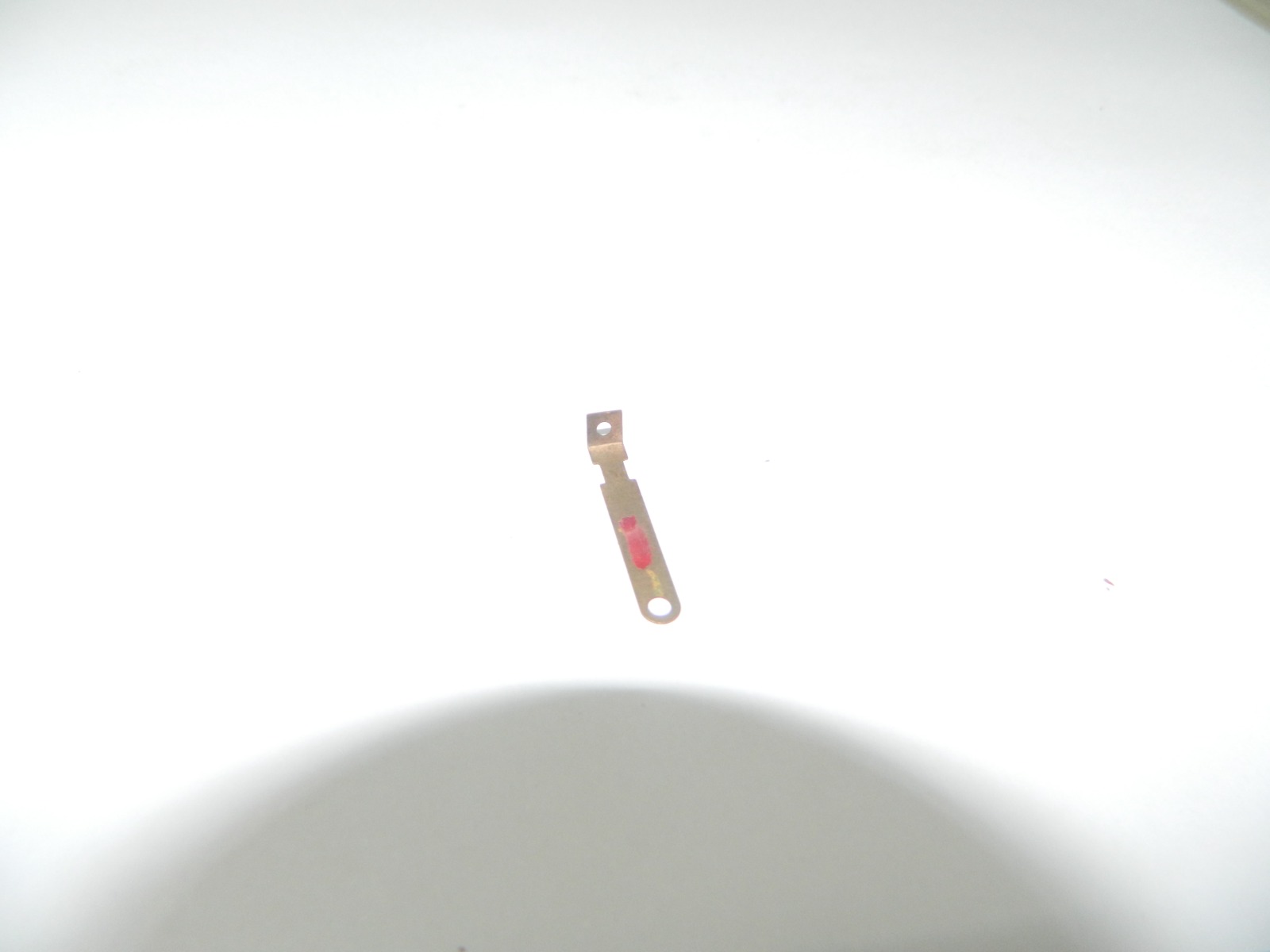

Metal Stamping Parts

Metal Stamping Parts Manufacturer

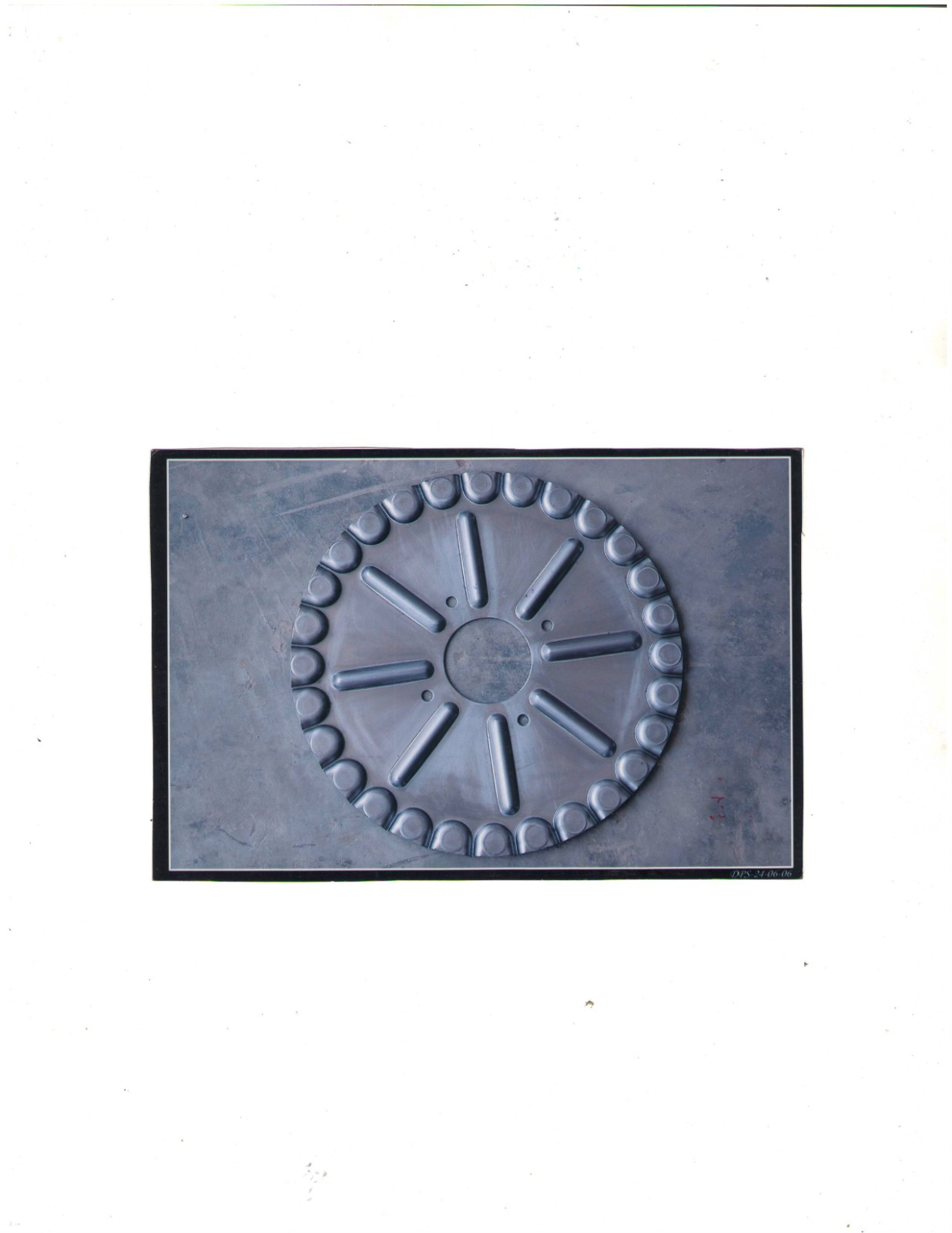

Metal stamping parts are integral components in various industries, known for their precision, durability, and versatility. This manufacturing process transforms flat sheet metal into specific shapes and sizes using a die and press. The process involves placing the metal sheet between the die and press, where the press applies force to shape the metal according to the design of the die. This method allows for the production of high-volume parts with consistent quality, making it a cost-effective solution for many applications.

One of the key advantages of metal stamping parts is their ability to maintain tight tolerances and produce complex geometries. This precision is crucial in industries such as automotive, aerospace, and electronics, where components must fit together perfectly and perform reliably under various conditions. Additionally, metal stamping parts can be produced at high speeds, making them ideal for large-scale manufacturing operations.

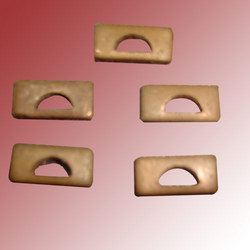

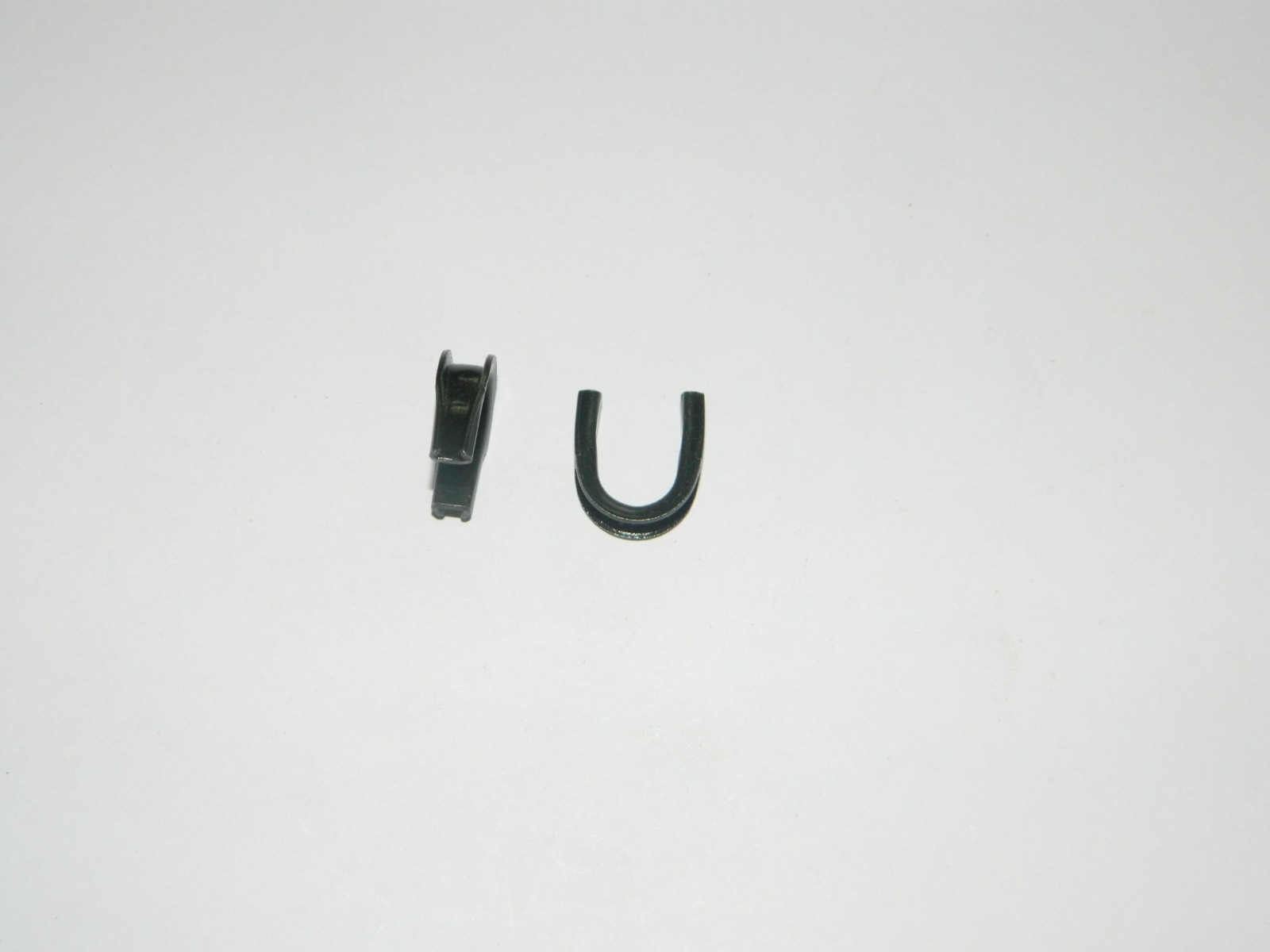

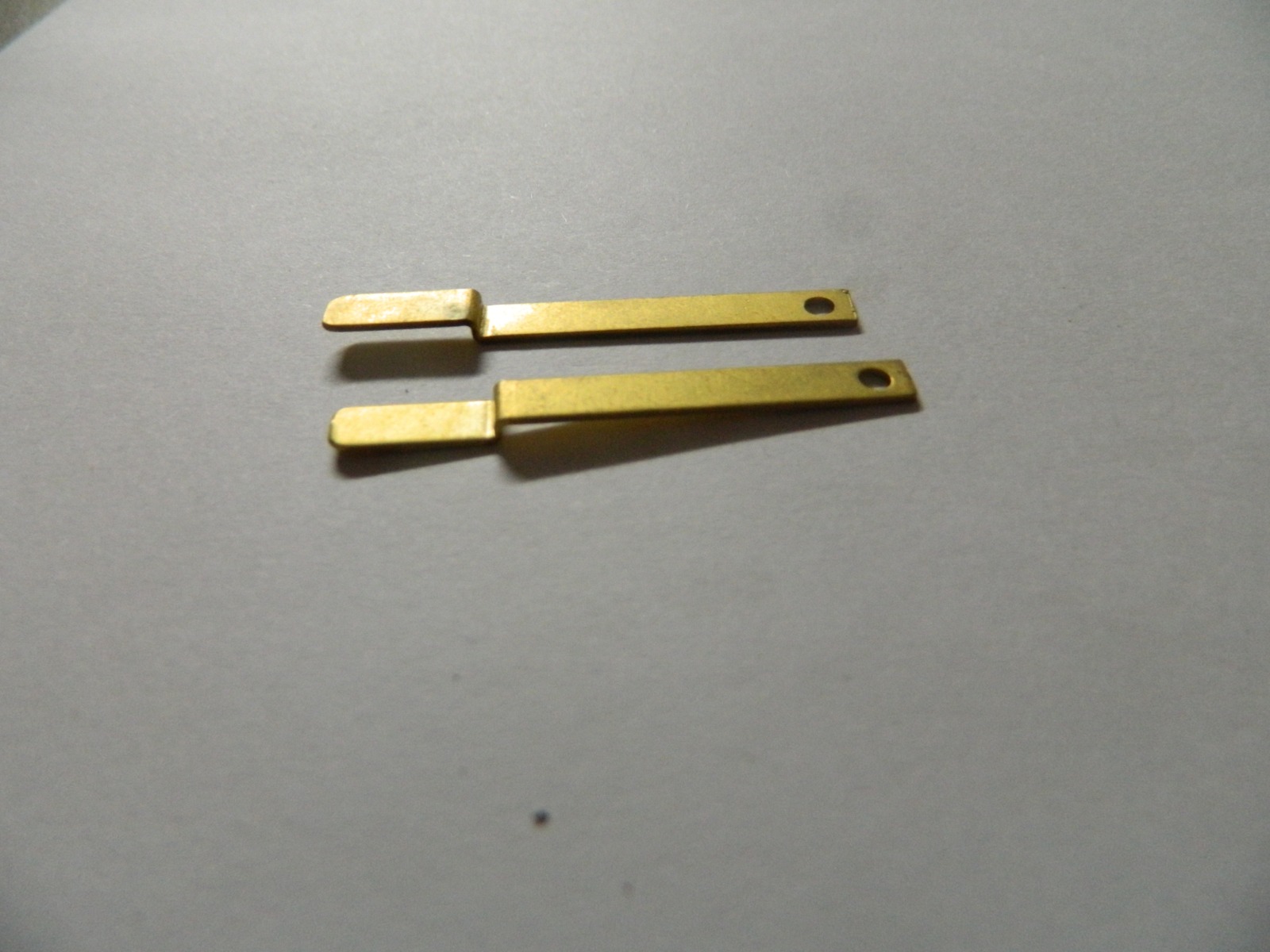

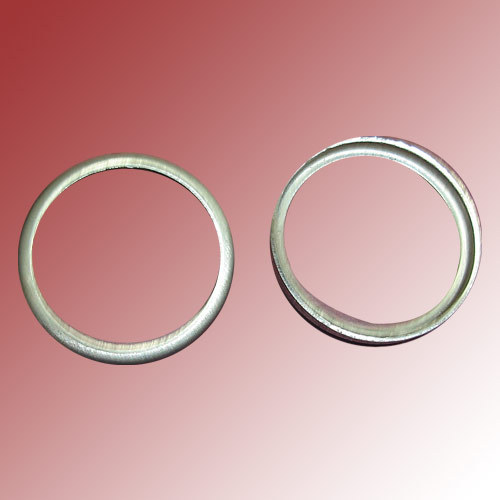

The materials used in metal stamping parts can vary depending on the application and requirements. Common materials include steel, aluminum, copper, and brass, each offering unique properties such as strength, conductivity, and corrosion resistance. These materials are chosen for their suitability to specific applications, ensuring that the stamped parts meet the functional and performance requirements of the end product.

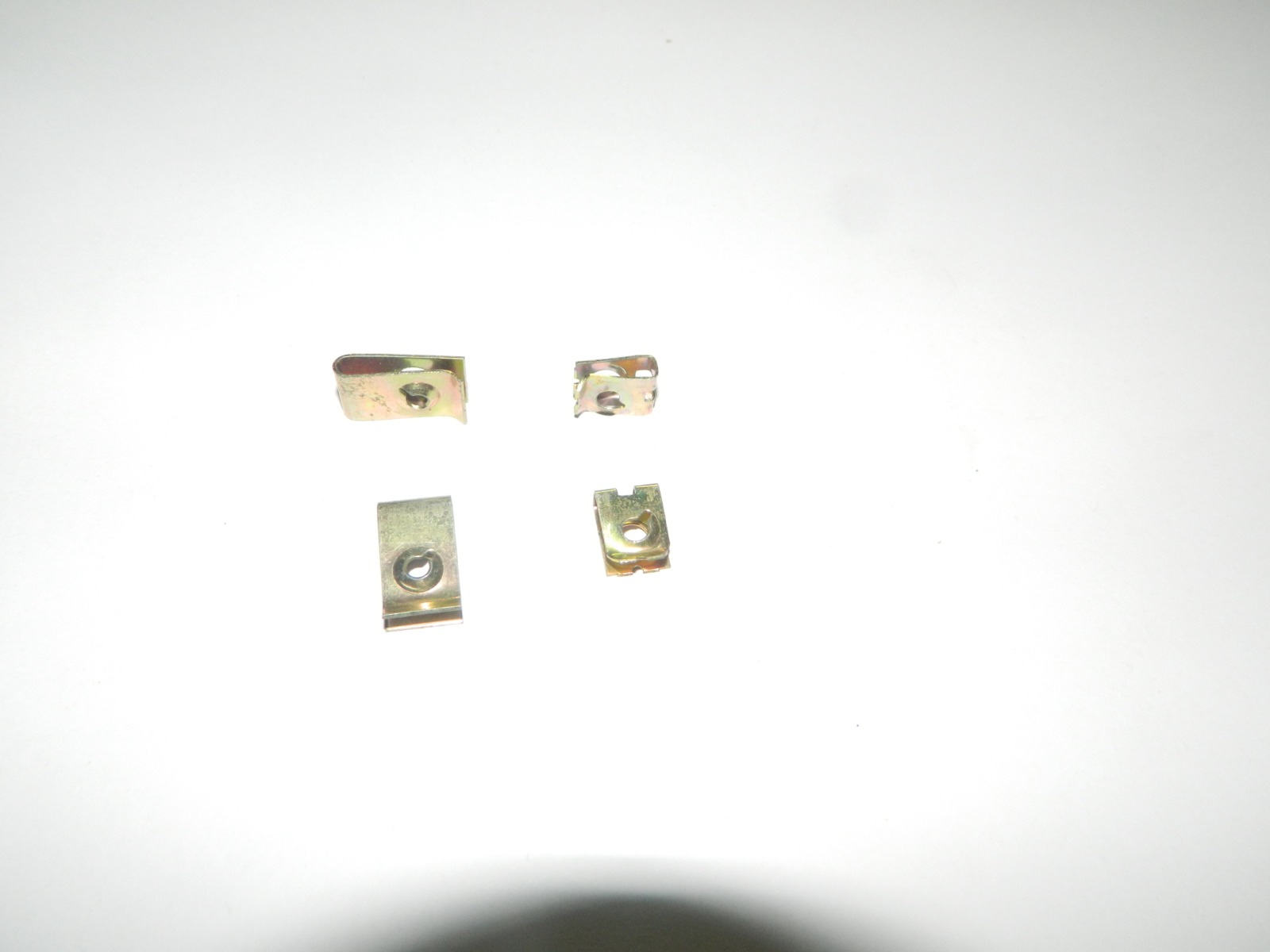

Metal stamping parts find applications across a wide range of industries. In the automotive industry, they are used for producing brackets, clips, and connectors. In the aerospace sector, they play a vital role in manufacturing structural components and assemblies. In the electronics industry, they are essential for producing connectors, contacts, and shielding. Their versatility and adaptability make them indispensable in construction, appliances, and many other sectors.

Quality control is paramount in the production of metal stamping parts. Rigorous testing and inspection processes ensure that each part meets industry standards and customer specifications. This includes dimensional checks, material analysis, and functional testing to guarantee the highest quality and reliability. By maintaining stringent quality control measures, manufacturers can ensure that metal stamping parts not only meet but often exceed customer expectations, making them a preferred choice for many industries.

In conclusion, metal stamping parts are versatile, cost-effective, and precision-engineered components that play a crucial role in various industries. Their ability to maintain tight tolerances, produce complex geometries, and be produced at high speeds makes them an ideal solution for a wide range of applications. Whether it's automotive, aerospace, electronics, or construction, metal stamping parts continue to be an integral part of modern manufacturing, driving innovation and excellence across industries.