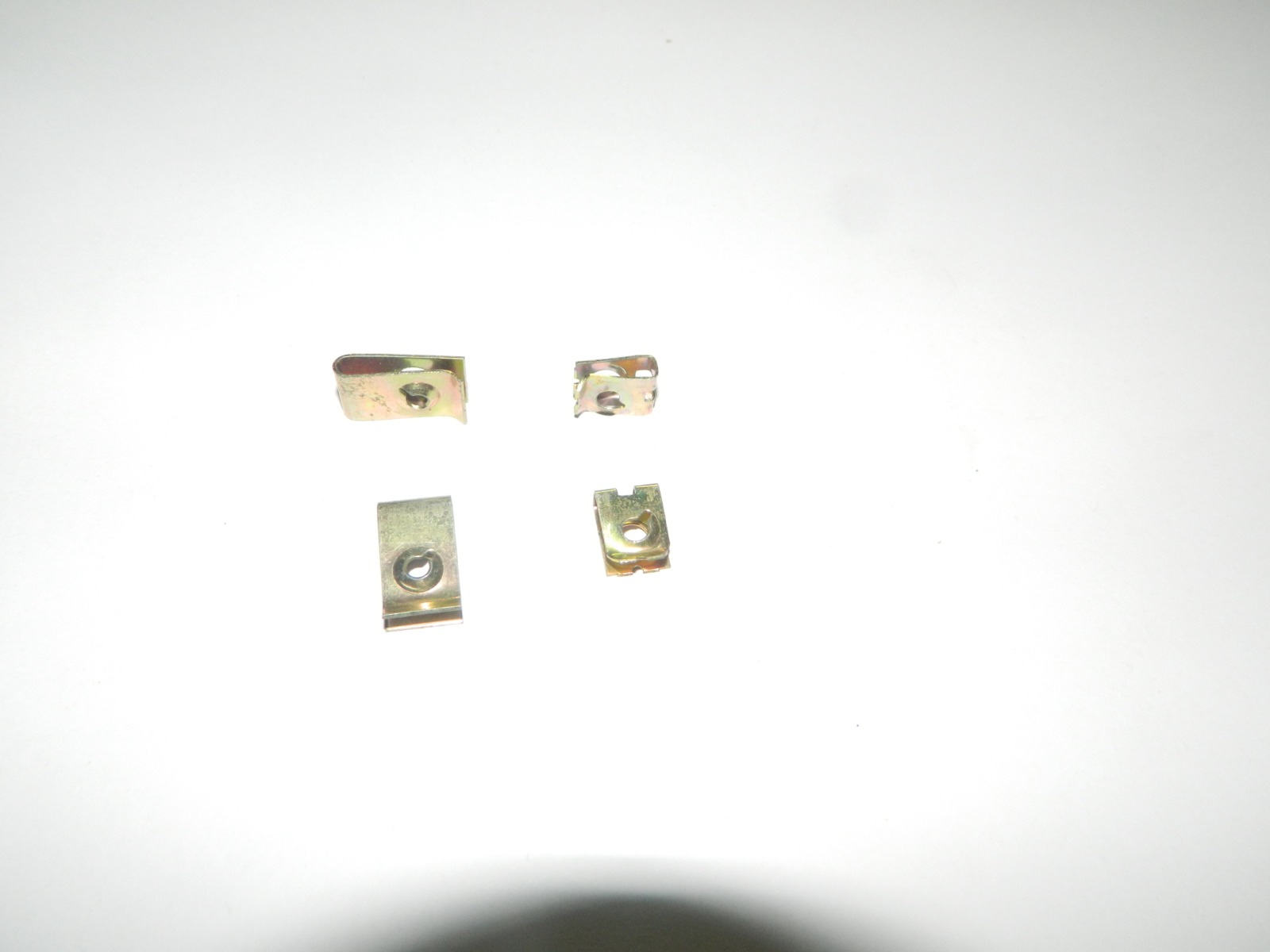

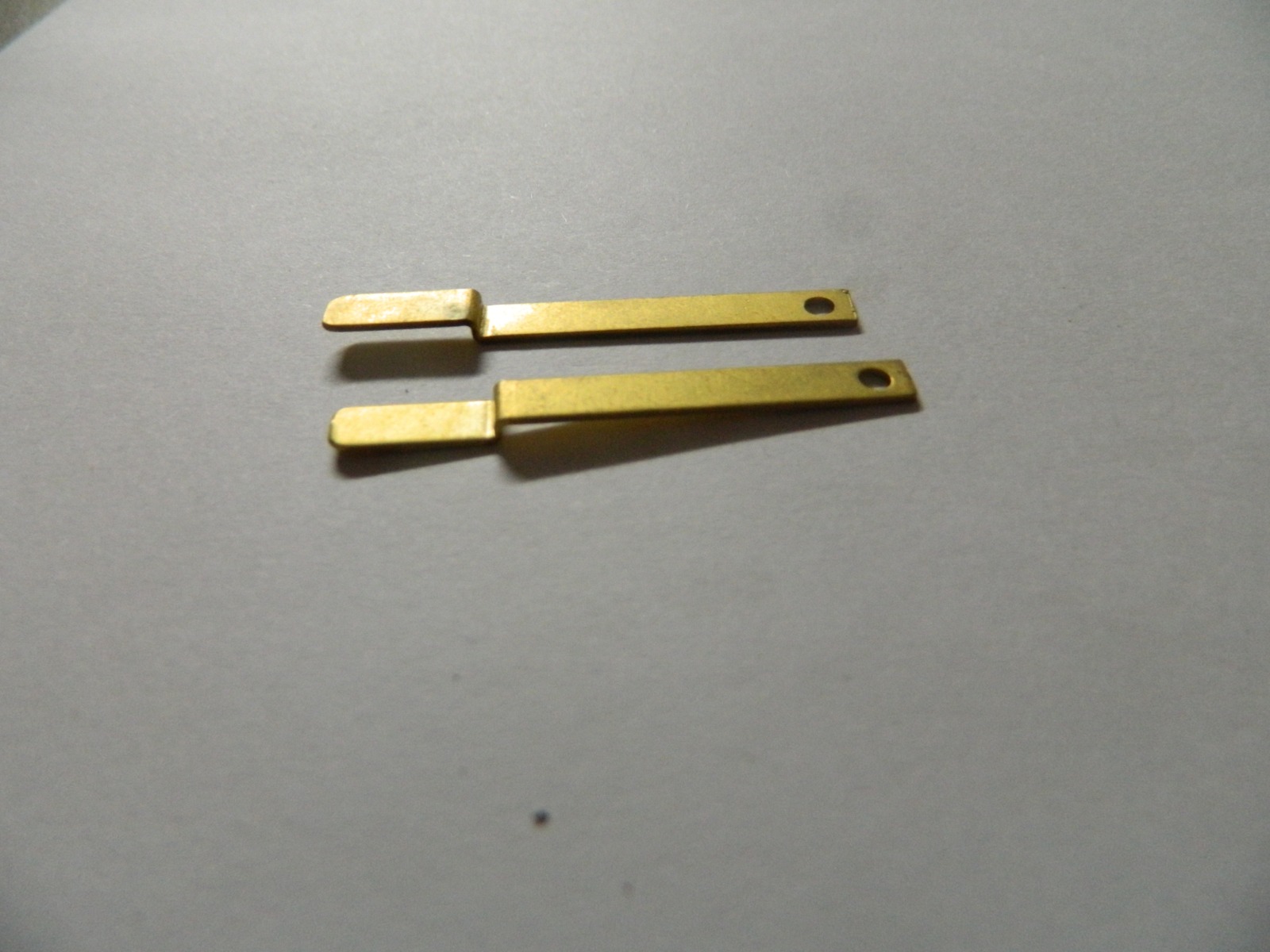

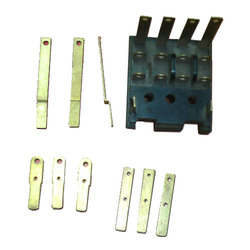

SS Sheet Metal Parts

SS Sheet Metal Parts Manufacturer

"SS" typically stands for "Stainless Steel," is an alloy primarily composed of iron, chromium, and nickel, known for its resistance to corrosion, durability, and sleek appearance. Stainless Steel (SS) sheet metal parts are components crafted from stainless steel sheets, an alloy primarily composed of iron, chromium, nickel, and other elements. The term "Stainless Steel" refers to its ability to resist stains, corrosion, and rust, making it a popular choice for a wide range of applications. Stainless steel parts are valued for their strength, durability, aesthetic appeal, and resistance to various environmental factors.

Superior Strength and Durability

Stainless Steel sheet metal parts are known for their superior strength and durability. This makes them ideal for applications requiring robust and long-lasting components. Whether it's heavy-duty equipment, machinery parts, or structural components, stainless steel parts offer reliability and performance under demanding conditions.

Corrosion and Rust Resistance

One of the key advantages of Stainless Steel is its excellent corrosion and rust resistance. This resistance to oxidation ensures that Stainless Steel sheet metal parts maintain their appearance and functionality even in harsh environments. It also reduces the need for maintenance and extends the lifespan of the components.

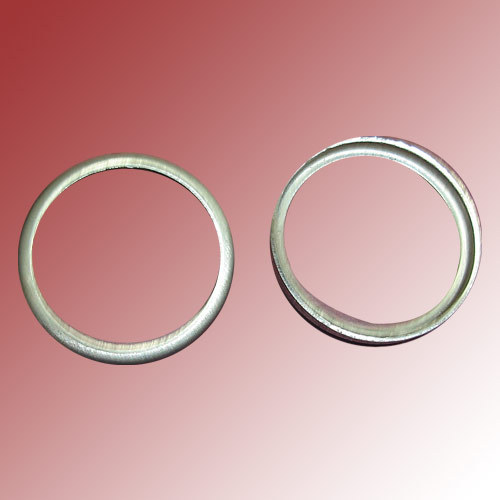

Aesthetic Appeal

Stainless Steel sheet metal parts offer a sleek and modern appearance, making them a popular choice for architectural, decorative, and high-end applications. The smooth and polished finish of Stainless Steel adds a touch of elegance and sophistication to any design, enhancing the overall aesthetic appeal.

Hygienic and Easy to Clean

Stainless Steel has a non-porous surface, making it hygienic and easy to clean. This property makes Stainless Steel sheet metal parts suitable for applications in healthcare, food processing, and sanitary environments where cleanliness and hygiene are paramount.

Quality Assurance

Quality control is crucial in the manufacturing of Stainless Steel sheet metal parts. Rigorous testing and inspection processes are implemented to ensure that each component meets industry standards, regulatory requirements, and customer specifications. This includes dimensional checks, material analysis, surface finish assessment, and functional testing to guarantee the highest quality, durability, and reliability.

Expertise in Stainless Steel Fabrication

Fabricating Stainless Steel sheet metal parts requires specialized skills and expertise due to the unique properties and characteristics of Stainless Steel. Our team of experienced professionals possesses the knowledge and capabilities required for precision Stainless Steel fabrication. From material selection to design, manufacturing, and quality control, we ensure that every Stainless Steel sheet metal part is crafted with meticulous attention to detail, ensuring optimal performance, durability, and customer satisfaction.

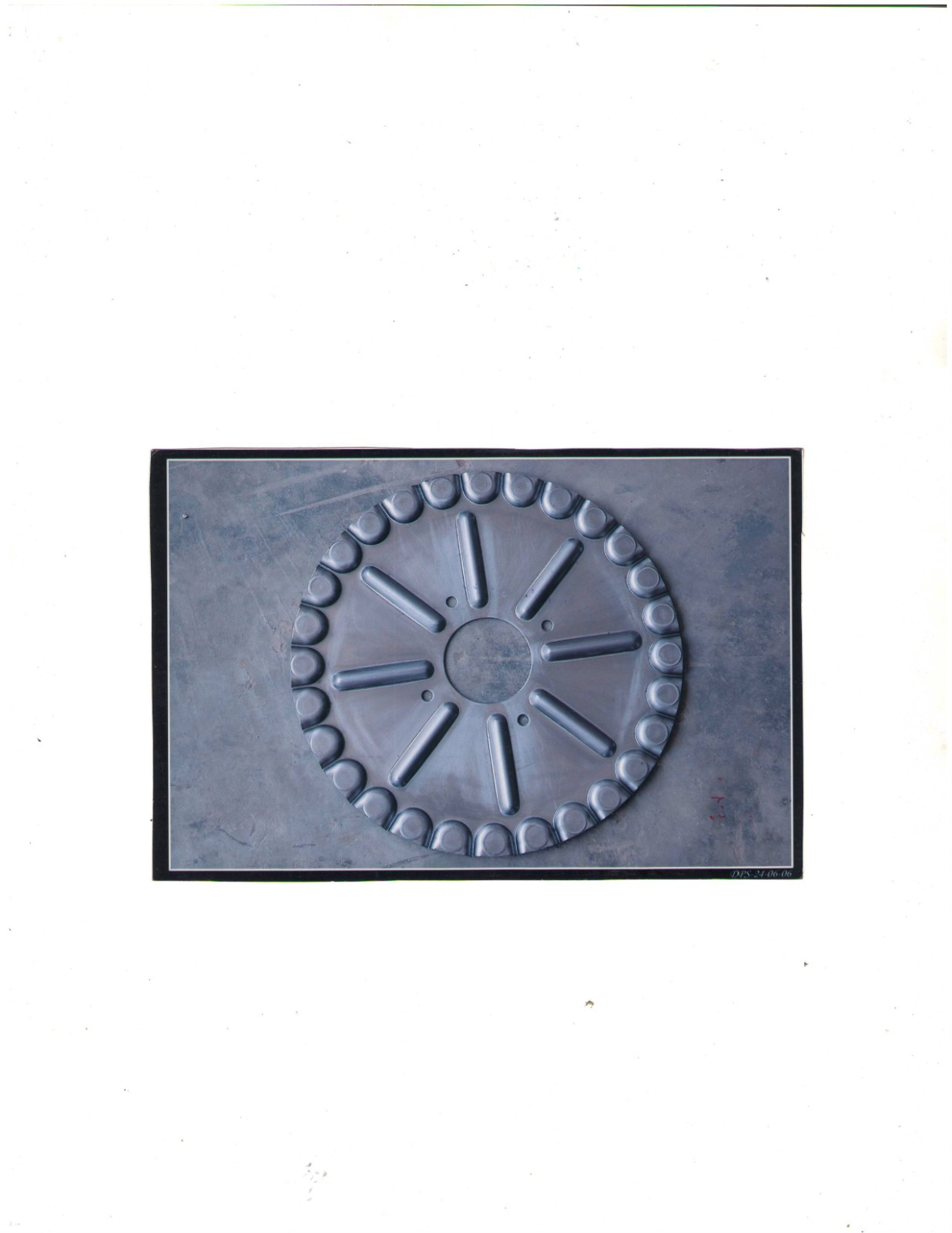

Applications of Stainless Steel Sheet Metal Parts

- Healthcare Industry: Medical equipment, surgical instruments, and hospital fixtures

- Food Processing: Machinery parts, food handling equipment, and storage containers

- Automotive Industry: Exhaust systems, automotive trim, and engine components

- Construction Sector: Architectural features, structural components, and building facades

- Marine Industry: Boat fittings, marine hardware, and nautical equipment

- Industrial Applications: Machinery parts, equipment enclosures, and manufacturing tools

In conclusion, Stainless Steel sheet metal parts offer a combination of unique properties, including superior strength, corrosion resistance, aesthetic appeal, hygienic properties, and recyclability. With meticulous engineering, precision manufacturing, expert fabrication, and stringent quality control, these parts provide reliable performance, longevity, and versatility across various applications.